The Challenge: Internal Corrosion and Cavitation Threaten Equipment Integrity

At a major petrochemical facility in the Gulf region, a large carbon steel pressure vessel measuring 108 inches (9 feet) in diameter was showing signs of severe internal corrosion and cavitation. These issues posed an increasing risk of leaks, operational downtime, and costly safety incidents..

Traditional repair options like welding were deemed too risky due to the explosive nature of the working environment, especially with regional temperatures soaring up to 50°C (122°F). Full replacement of the vessel was not a feasible option due to long lead times and high costs. The customer needed a fast, safe, and cost-effective repair solution that could be applied on-site and inside the vessel.

The Solution: Devcon® Cold-Applied Composite Repair System

To restore the pressure vessel and protect it from further corrosion, the facility selected a cold-applied, non-invasive solution using:

- Devcon® Titanium Putty – a high-performance metal repair compound for rebuilding surfaces.

- Devcon® Brushable Ceramic Blue – a durable ceramic-filled epoxy coating designed for corrosion resistance and fluid flow enhancement.

Step-by-Step Application Process:

-

Surface Preparation

The internal surface of the vessel was grit blasted to SA3 – SSPC-SP5 standards, achieving a surface profile of 80μ–90μ. This ensured optimal adhesion of the repair materials. -

Anomaly Rebuild with Devcon® Titanium Putty

Parts A and B of the Titanium Putty were thoroughly mixed using a 3” spatula and applied to fill all pitting, cavitation marks, and other surface defects. Once cured, the repaired areas were uniform and smooth. -

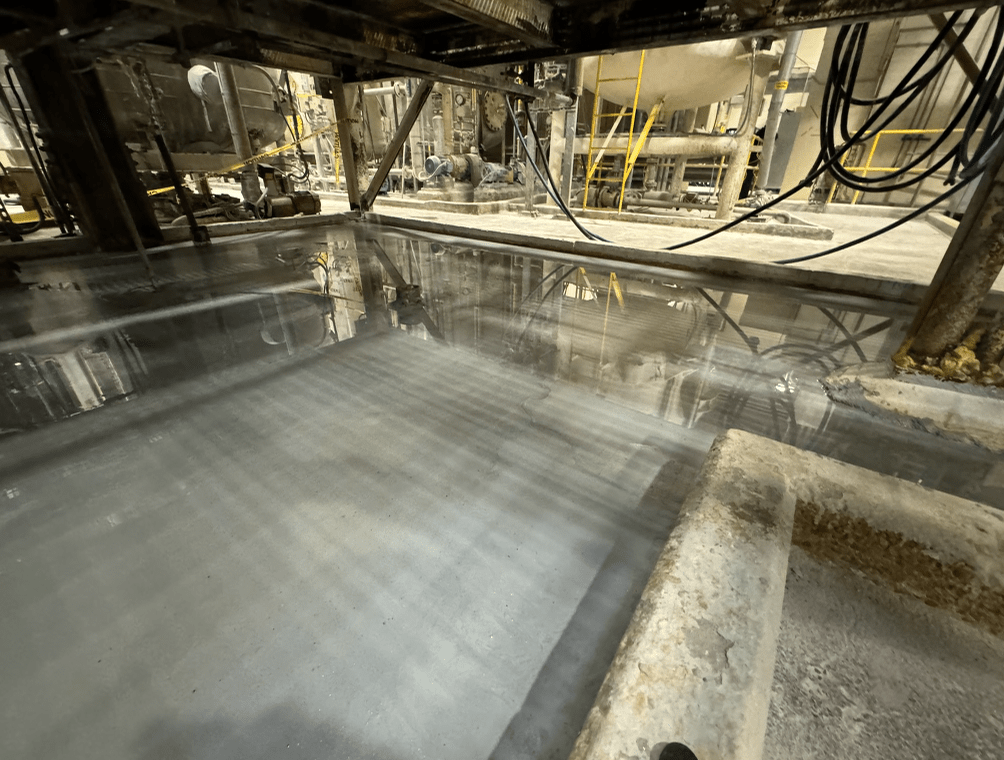

Protective Coating with Brushable Ceramic

A brush-applied coat of Devcon® Brushable Ceramic was added to form a seamless protective barrier. The Wet Film Thickness (WFT) was measured between 350–500 microns to meet application specifications. A second coat was applied for added durability. Final inspection with a holiday detector confirmed there were no pinholes or defects.

Project Outcome: Long-Term Protection & Fast Turnaround

Long-Lasting Corrosion Protection

The combination of Devcon® Titanium Putty and Brushable Ceramic created a high-integrity protective lining, restoring the vessel’s interior to its intended condition and shielding it from future erosion, corrosion, and cavitation.

Safe & Cold-Applied Installation

The Devcon® system offered a cold-weld alternative—eliminating the risks associated with hot work such as welding in potentially explosive environments. This aligns with Devcon's mission since 1947: enabling industrial repair without dangerous hot work.

Fast, Cost-Effective Results

Thanks to Devcon’s ease of use and fast-curing properties, the entire repair process was completed within hours—minimizing downtime, avoiding costly equipment replacement, and lowering overall maintenance expenses.

Why Choose Devcon® for Pressure Vessel Repair?

Devcon® repair solutions are trusted in critical infrastructure environments for their:

- Exceptional adhesion and chemical resistance

- Fast return-to-service capability

- Proven safety in volatile, high-temperature conditions

Whether it’s corrosion, pitting, or wear from fluid impact, Devcon’s high-performance coatings and putties are engineered to extend the life of industrial assets—safely, quickly, and economically.

Want to learn how Devcon® can solve your maintenance challenges? Contact us today.

发表评论

所有评论在发布前都会经过审核。

此站点受 reCAPTCHA 保护,并且 Google 隐私政策和服务条款适用。